BENDAPTIVE

The fields of bending application are many as bending sheet metal, even more so with the use of a press brake, is one of the best and cheapest ways to run prototypes and batches even in very small series.

Today companies are called to respond to the modern challenge of finding efficient and flexible configurations and processes in order to follow up on the latest demands of the industrial world.

Our systems have been designed to guarantee productivity performance on large batches but at the same time, thanks to the easy programming due to offline systems, a high-performance tracking system and automatic press tooling, they allow the necessary flexibility to justify its use even on small batches, guaranteeing enviable accuracy to the most experienced bender!

FOCUS POINTS

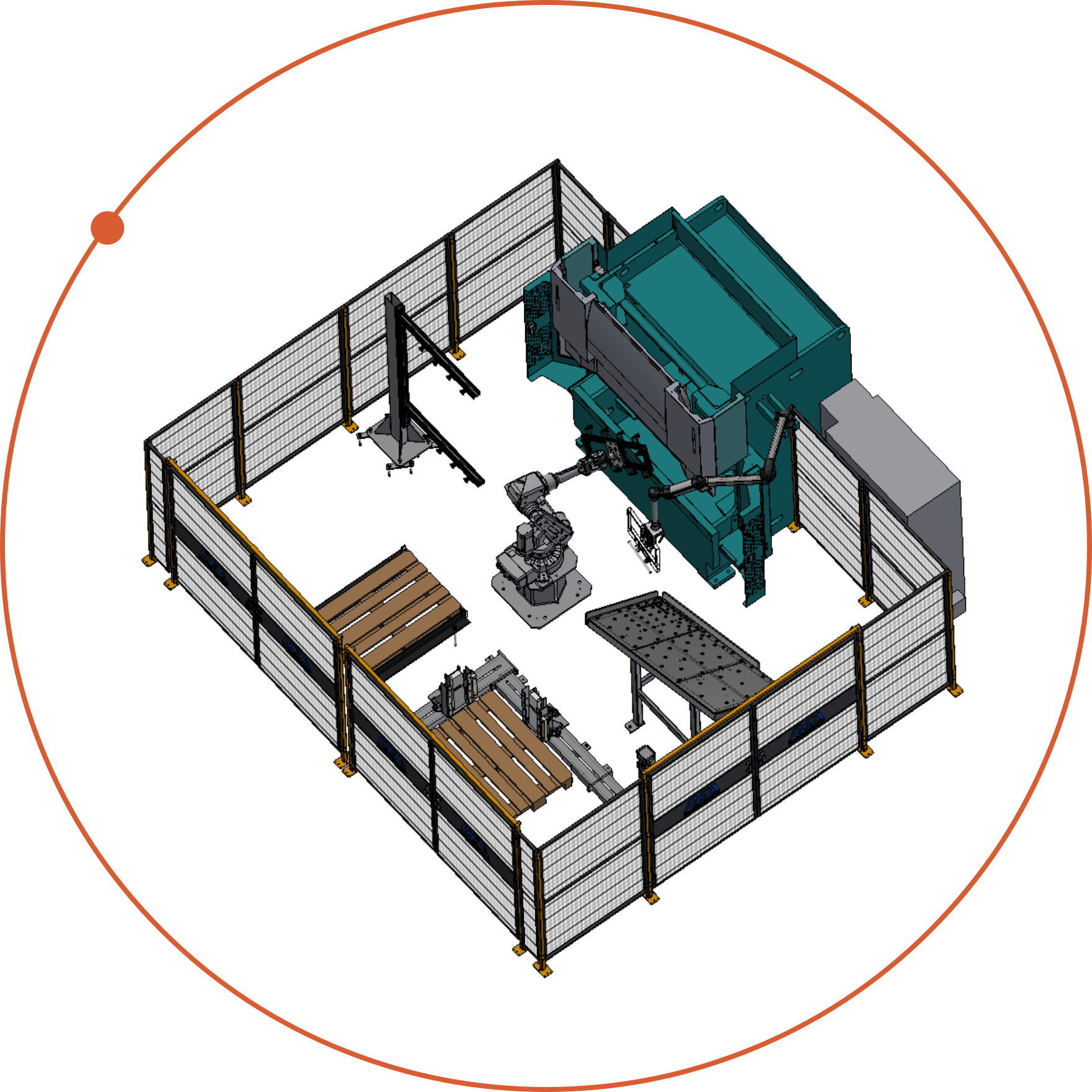

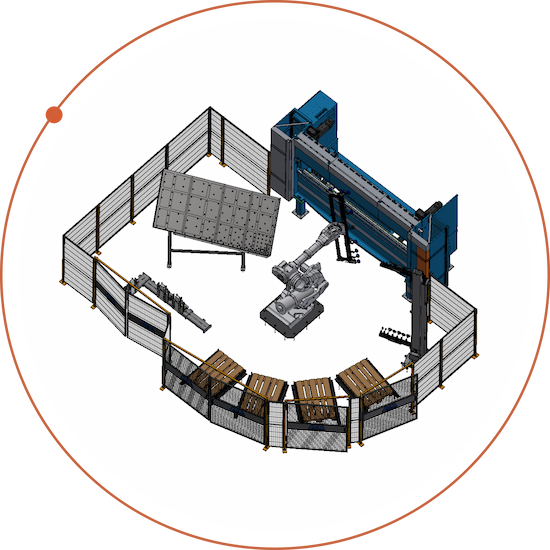

BendAptive SMART

BendAptive Smart solution was created to meet production needs for press brake tending with length up to 2,000 mm and for process sheet metal with a maximum weight of 10 kg with reach up to 1.65m.

PRESS BRAKE FEATURES:

- Max force 50-60 t

- Max length 2000 mm

BASIC VERSION COMPOSITION:

- Robot with raised baseplate

- Dynamic tracking system

- Nr 1 gripper with suction cups

- Sheet sorter with magnets / brushes

- Contactless laser thickness control device

- Sheet centering device with inclined plane

- Vertical tipper with fixed arms

- Perimeter Safety Fences

- Installation and testing on site

- 5-days REA training course (ABB knowledge)

BendAptive SMART

BendAptive Smart solution was created to meet production needs for press brake tending with length up to 2,000 mm and for process sheet metal with a maximum weight of 10 kg with reach up to 1.65m.

PRESS BRAKE FEATURES:

- Max force 50-60 t

- Max length 2000 mm

BASIC VERSION COMPOSITION:

- Robot with raised baseplate

- Dynamic tracking system

- Nr 1 gripper with suction cups

- Sheet sorter with magnets / brushes

- Contactless laser thickness control device

- Sheet centering device with inclined plane

- Vertical tipper with fixed arms

- Perimeter Safety Fences

- Installation and testing on site

- 5-days REA training course (ABB knowledge)

- Workable pieces: Sheets with a maximum weight of 10 Kg

- ABB IRB 2600-20/1.65

- Payload 20 Kg

- Reach 1.65m

- Axis number: 6

- IRC5/OMNICORE Control Unit

- Bending OFF-LINE software

- Integrated motion track for robot (7th axis)

- Motorized tipper

- Sheet loader

- Automatic gripper gearbox

- Automatic press tool changer

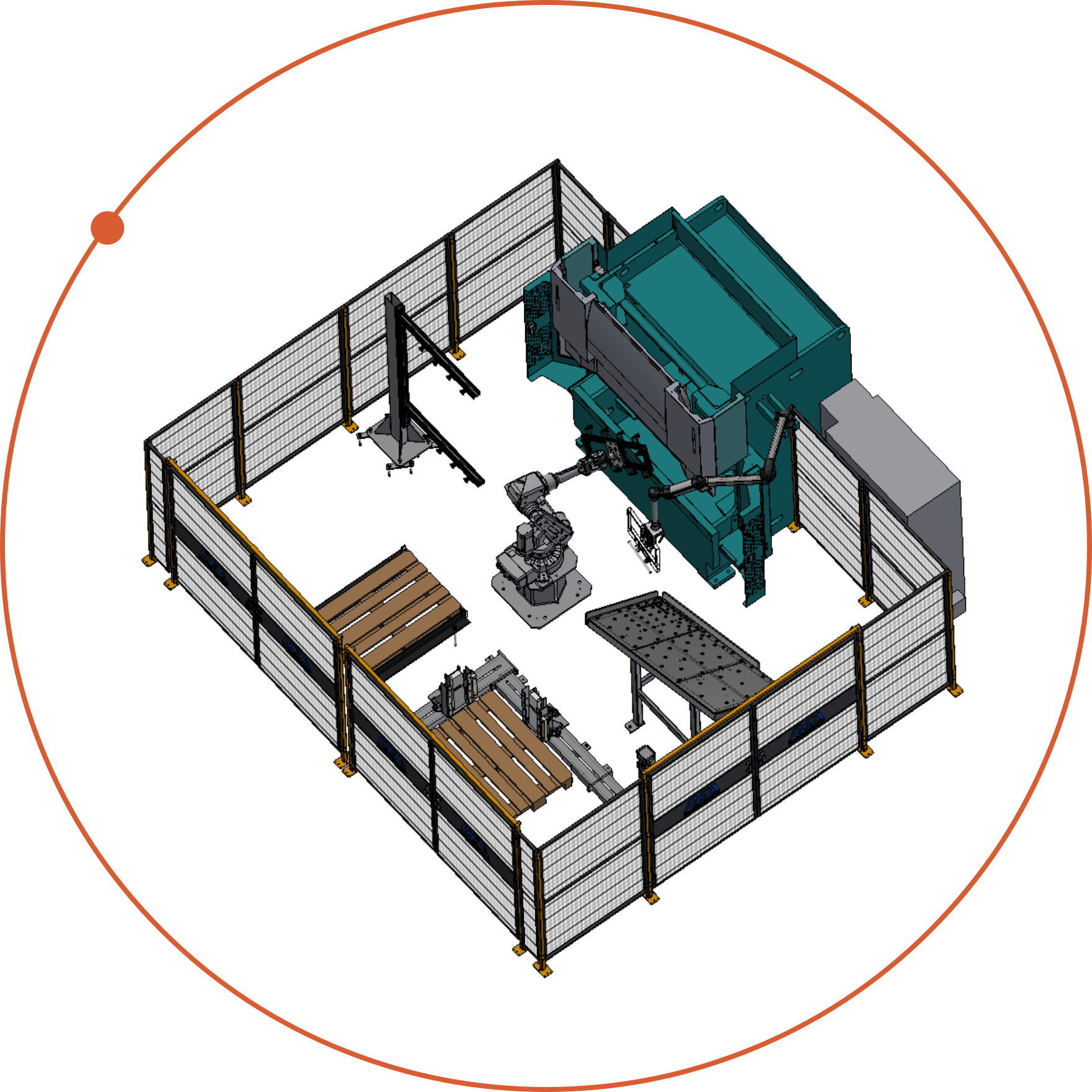

BendAptive FLEX

BendAptive Flex solution was created to meet production needs for press brake tending with length up to 3,000 mm and for process sheet metal with a weight between 20Kg and 45 Kg with reach up to 2.70m

PRESS BRAKE FEATURES:

- Max force 100-130 t

- Max length 3000 mm

BASIC VERSION COMPOSITION:

- Robot with raised baseplate

- Dynamic tracking system

- Nr 1 gripper with suction cups

- Sheet sorter with magnets / brushes

- Contactless laser thickness control device

- Sheet centering device with inclined plane

- Vertical tipper with fixed arms

- Perimeter Safety Fences

- Installation and testing on site

- 5-days REA training course (ABB knowledge)

- Workable pieces: Sheets with a maximum weight of 20 – 45 Kg

- IRB 4600-40/2.55 or IRB 5710-90/2.70

- Payload 40 Kg (4600-40/2.55) – 90 kg (5710-90/2.70)

- Reach 2.55 m – 2.70 m

- Axis number: 6

- IRC5/OMNICORE Control Unit

- Bending OFF-LINE software

- Integrated motion track for robot (7th axis)

- Motorized tipper

- Sheet loader

- Automatic gripper gearbox

- Automatic press tool changer

BendAptive PRO

BendAptive Pro solution was created to meet production needs for press brake tending with length up to 4,000 mm and for process sheet metal with a maximum weight of 100 kg with reach between 3.0 m e 3.5 m

PRESS BRAKE FEATURES:

- Max force 200-220t

- Max length 4000 mm

BASIC VERSION COMPOSITION:

- Robot with raised baseplate

- Dynamic tracking system

- Nr 1 gripper with suction cups

- Sheet sorter with magnets / brushes

- Contactless laser thickness control device

- Motorized vertical tipper

- Perimeter Safety Fences

- Installation and testing on site

- 5-days REA training course (ABB knowledge)

BendAptive PRO

BendAptive Pro solution was created to meet production needs for press brake tending with length up to 4,000 mm and for process sheet metal with a maximum weight of 100 kg with reach between 3.0 m e 3.5 m

PRESS BRAKE FEATURES:

- Max force 200-220t

- Max length 4000 mm

BASIC VERSION COMPOSITION:

- Robot with raised baseplate

- Dynamic tracking system

- Nr 1 gripper with suction cups

- Sheet sorter with magnets / brushes

- Contactless laser thickness control device

- Motorized vertical tipper

- Perimeter Safety Fences

- Installation and testing on site

- 5-days REA training course (ABB knowledge)

- Workable pieces: Sheets with a maximum weight of 60 – 100 Kg

- IRB 6650S-125/3.50 or IRB 6650S-200/3.00

- Payload 125 kg (6650S-125/3.50) – 200 Kg (6650S-200/3.00)

- Reach 3.5 m – 3.0 m

- Axis number: 6

- IRC5/OMNICORE Control Unit

- Bending OFF-LINE software

- Integrated motion track for robot (7th axis)

- Sheet loader

- Automatic gripper gearbox

- Automatic press tool changer