Revamping e retrofit

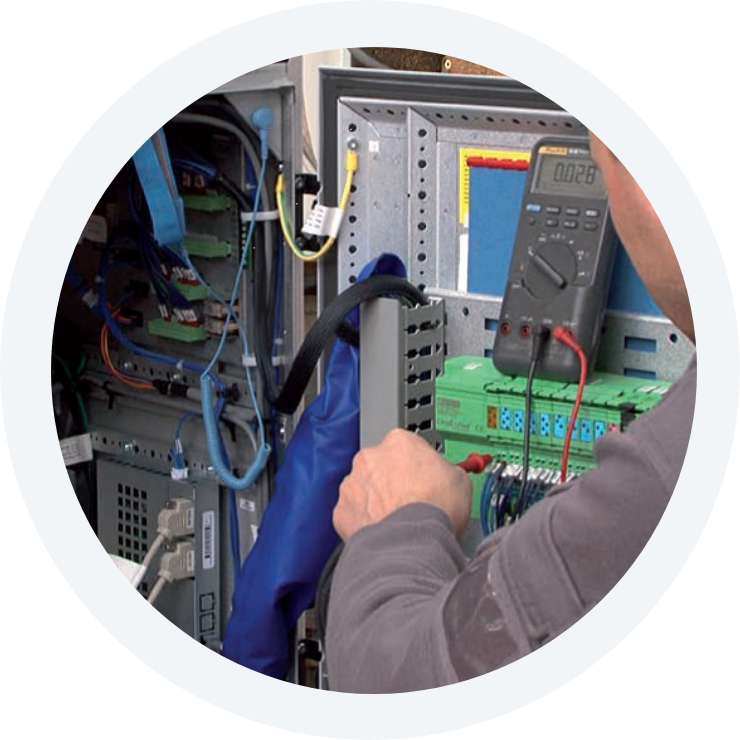

In addition to production stress, robotic systems are also subjected to continuous technological evolutions that sometimes involve the need to assess their replacement in order to increase productivity, reduce the risks of inefficiency or even modify their intended use for conversion to a new production.

Thanks to its experience, REA Robotics is able to offer advice regarding revamping or retrofitting operations based on the set-up’s state of wear and the client’s production needs.

Through revamping operations, the existing systems are disassembled and checked before extraordinary maintenance is carried out in order to restore everything to a higher and more precise degree of performance compared to the current state, without altering the machine’s electronics.

With retrofitting, rather, based on the robot model, the electronics of the systems are inspected and certain components are replaced (such as the panel, generator, and so on).

Thanks to this, it is possible to guarantee suitable cycle times and extend the productive life of the machine along with a return on investment in no time at all.

Revamping e retrofit

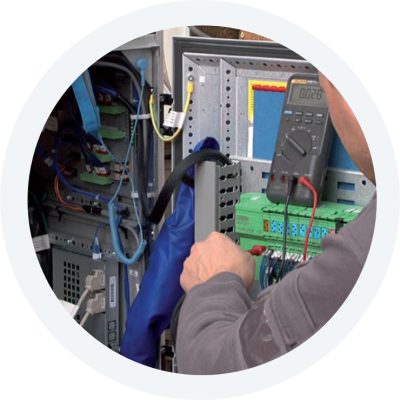

In addition to production stress, robotic systems are also subjected to continuous technological evolutions that sometimes involve the need to assess their replacement in order to increase productivity, reduce the risks of inefficiency or even modify their intended use for conversion to a new production.

Thanks to its experience, REA Robotics is able to offer advice regarding revamping or retrofitting operations based on the set-up’s state of wear and the client’s production needs.

Through revamping operations, the existing systems are disassembled and checked before extraordinary maintenance is carried out in order to restore everything to a higher and more precise degree of performance compared to the current state, without altering the machine’s electronics.

With retrofitting, rather, based on the robot model, the electronics of the systems are inspected and certain components are replaced (such as the panel, generator, and so on).

Thanks to this, it is possible to guarantee suitable cycle times and extend the productive life of the machine along with a return on investment in no time at all.